Sterilization is an important process in the production of canned food products. It is required by law in most countries and provides a safe way to produce a shelf-stable food product. This process uses heat to kill microorganisms and makes the contents sterile.

The acidity of food is an important factor for canning, as it affects the heat resistance of microorganisms. Acids penetrate living bacteria cells and break them up into ions, which cause cell death. High acidity of food causes the general sterilization temperature to be lower and the time to sterilize shorter. Flat cans, however, transfer heat faster than low-profile tanks.

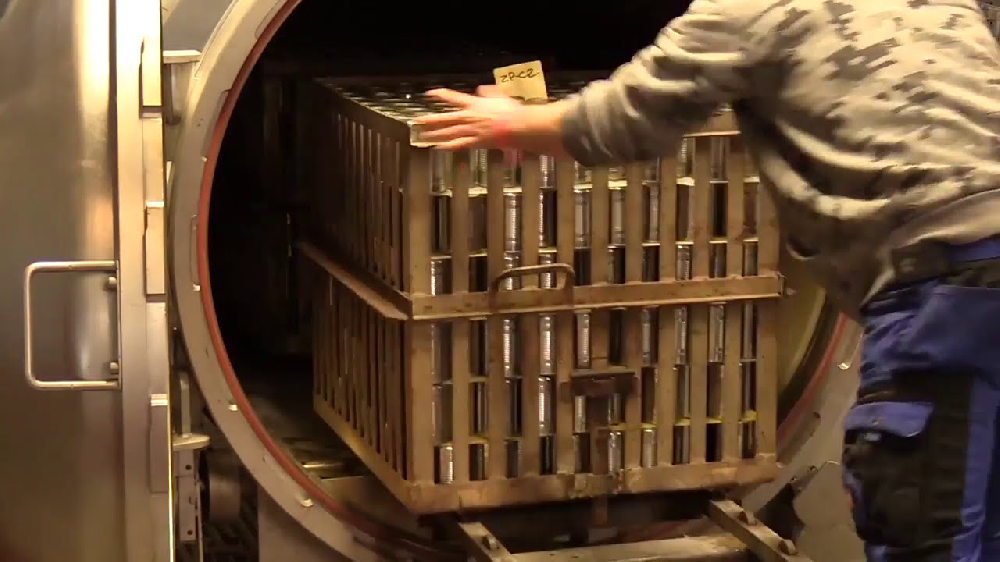

In-container sterilization

This method of sterilizing canned food involves heating the food to a temperature of 130 to 145 degrees Celsius and holding it there for the required amount of time. The temperature and time required will depend on the type of product and container. However, a flat, laminated pouch will decrease the amount of heat damage.

The process of sterilization is a key element in the preservation of food. The temperature at which it is carried out will determine whether the food is safe or not. A high temperature kills microorganisms, which are present in the food. It also kills the enzymes that cause spoilage, which prevents the growth of toxins in the food.

The time and temperature required for in-container sterilization of canned food depends on the microorganisms on the food, the size of the container, and the acidity of the food. Thermal processes for canning destroy the spores of Clostridium botulinum, a bacterium which can cause food poisoning. However, this method does not kill all of the other microorganisms present in the food.

After undergoing this process, canned foods should be stored in a cool, dark place. Ideally, they should be stored at a temperature between 50 and 70 degrees Fahrenheit. They should not be stored near hot ranges, pipes, or in direct sunlight, because they lose their quality within a few weeks and may even spoil. Also, dampness can lead to leaks, and metal lids may become corroded or damaged.

High pressure thermal sterilization

The process of high pressure thermal sterilization for canned food involves heating food in a sealed cylinder under high pressure for a specific amount of time. The high pressure process can produce a superior quality product while minimizing pre-heating and post-processing heat damage. The process can be carried out by using a pressure vessel containing a variety of fluids, each with its own adiabatic heating properties. These fluids include water/emulsions, glycerol, and edible oils.

The length of the sterilization process depends on the size and type of metal containers used. Different metal containers require different heating times. Different cans have different cold points, and the centre of the can requires a longer period to heat. For example, tall cans need a longer time to heat to their cold point, and short cans need less time to reach that point.

High pressure thermal sterilization for canned food can be done with two techniques. One involves pulsed high pressure, while the other uses continuous high pressure. In pulsed high pressure, the initial pressure is 60 MPa and the initial temperature is 70degC. The second pressure pulse is 500 MPa, and the process repeats 10 times. The first pressurization triggers the germination of spores, while the second one destroys vegetative cells. After high pressure testing, the samples are microbiologically tested for growth and signs of deterioration. The final re-cooling period is ten days at 37degC.

There are several benefits to high pressure thermal sterilization for canned foods. The process can create uniform, minimally processed food products, and improve food quality. Despite its advantages, high pressure thermal sterilization for canned food is not widely used. It is not widely used in commercial production, and it hasn't yet been proven to work.

Inoculated pack technique

There are two primary methods for sterilizing canned food. One is the inoculated pack technique, which involves adding a live microorganism into the can before it is processed. The other is the continuous in-pack food sterilization technique, which uses the lowest temperature possible to sterilize the food.

The first method involves the use of a hot-air oven. The hot air inside the oven kills bacteria and other pathogenic microorganisms. This heat treatment results in a safe and effective food sterilization process. It also significantly reduces the number of spoilage-causing microorganisms in the canned food. It also destroys the enzymes responsible for microbial spoilage. The two methods have very different effects on food quality. The former produces minimal changes in sensory characteristics, while the latter causes significant changes in nutritional values and organoleptic properties.

The inoculated pack technique is useful for products that have large differences in heat penetration. This technique is particularly valuable for products where there is significant variation in the size of the can. It also eliminates the need for conducting experimental packs to test the effects of the process. Furthermore, it produces 'commercially sterile' canned food with the highest level of quality retention.

The thermal process used for commercial sterility kills the majority of pathogenic bacteria and heat-resistant organisms that would cause spoilage in the canned food. However, the recommended processes may not deal with excessive organisms present in the canned food. For this reason, it is vital that strict sanitation principles are followed prior to canning.

Copyright © 2003 Zhangzhou Can Food Co.,Ltd ICP15488684